To buy or not to buy leather? Is it eco friendly? A tough decision...

Leather's natural so it's good, right? Well, no, it's not that simple. Leather production remains a dirty business with many industry players still having a long way to go in terms of cleaning up their act. So is 'vegan leather' the answer? Well, no, that can be greenwashed hogwash too!

Leather is a by-product of the meat industry, which is the argument most often used in its favour. But the industry as a whole still leaves much to be desired in terms of minimising its impact on the environment, with tanneries in India, Morocco, Sri Lanka and Bangladesh causing major health problems for workers and huge environmental degradation. However, UK/EU companies such as Bridge of Weir have invested in cleaner tanning technologies and in the EU and the US, strict environmental legislation ensures effluent does not enter the water system. For more on Scottish leather producers' environmental policies see here

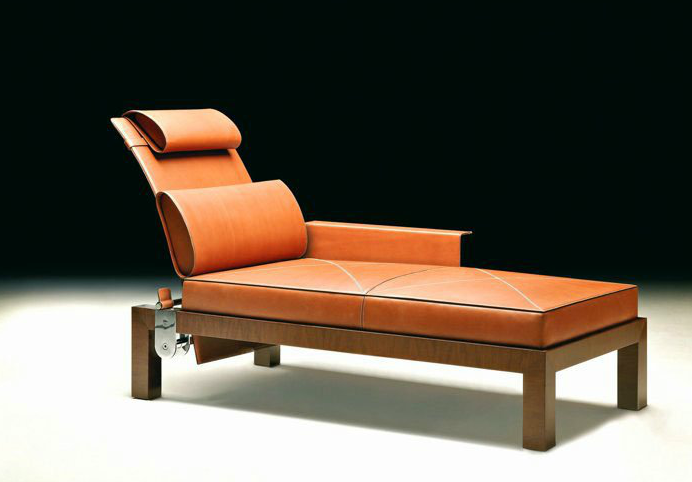

High quality leather is a wonderful material. It is beautiful, smells divine, can be buttery-soft yet hard-wearing, it's sophisticated yet comforting, and generally has a sumptuousness and richness about it. It ages well and can last for many decades.

But as with so many things we prize, a lot of us haven't got a clue about how it's been produced and frankly, it's easier to ask no questions and not look behind the curtain.

Leather is a by-product of the meat industry (itself subject to growing criticism for the environmental damage it's doing), and man has for millenia been preserving animal skins and putting them to use. Leather is also a sustainble product, given that the animals we use for leather aren't about to become extinct.

However, while the finished product can be deeply pleasing, and while big progress has been made in the EU at minimising hazardous waste from tanning, in countries such as India and Morocco toxic chemicals are widely used in tanneries and the effluent from them contaminates scarce water sources and causes illness to workers.

Turning raw hides into leather has always been a dirty job; after all, it takes powerful chemicals to stop the natural decomposition process of a dead animal. In the days when people tanned the hides of the animals they had just eaten for dinner, the process was often carried out using dog poo, quick lime and even human waste as well as kindlier vegetable tannins from oak leaves. Nowadays it still often involves the toxic heavy metal chromium that makes it a much faster but more treacherous process.

Human Rights Watch recently published a report on tanneries in Bangladesh, which supply leather to Europe and the US. It found a catalogue of horrors including child labour and workers with chronic skin damage and respiratory diseases from handling chromium, sulphuric acid, formaldehyde and bleach without protective clothing, and a local population suffering similar ailments from drinking water contaminated by chemical-laden effluent.

Yet at the same time, more leather producers are claiming that their product is a truly green and eco-friendly material – which means that it is down to consumers to try to differentiate between the saints and the sinners.

Greenpeace campaigner Lorena Pujo is based in Argentina and has seen how pressure from the public and groups like her own can create change. A decade ago Argentinian tanneries were using the highly carcinogenic Chromium 6 and discharging untreated water into the environment, now they have switched to the less toxic Chromium 3 and are beginning to clean up their act, although she says 'it’s still a hard fight'.

Stand up to disingenuousness

Meanwhile, Greenpeace has turned its attention to manufacturing companies, especially those in the fashion industry which are big end users of leather, with its Detox campaign which challenges them to remove toxic chemicals from their production.

'The key is the supply chain,' says Pujo. 'We are trying to make international brands commit to eliminating toxic chemicals. These big brands have suppliers in developing countries where standards are really low and they rarely consider the discharge of hazardous and persistent chemicals, as happens in Bangladesh. The finished products themselves meet the EU or US standards, but these standards don’t take into account the way the leather in the product has been produced.'

What makes it harder for the consumer is that product labelling is often vague – so a leather item labelled 'Made in Italy' means only that the leather had a surface treatment there, or the finished item was made there, not that the leather was actually tanned there, or indeed, that the cows were raised there. This makes it hard for the consumer to avoid giving business to tanneries that cause harm to workers and the environment.

Gucci has for some time offered series of bags that come with a 'passport' detailing the life history of the cow that made them, however such traceability is far from the norm.

Organic leather

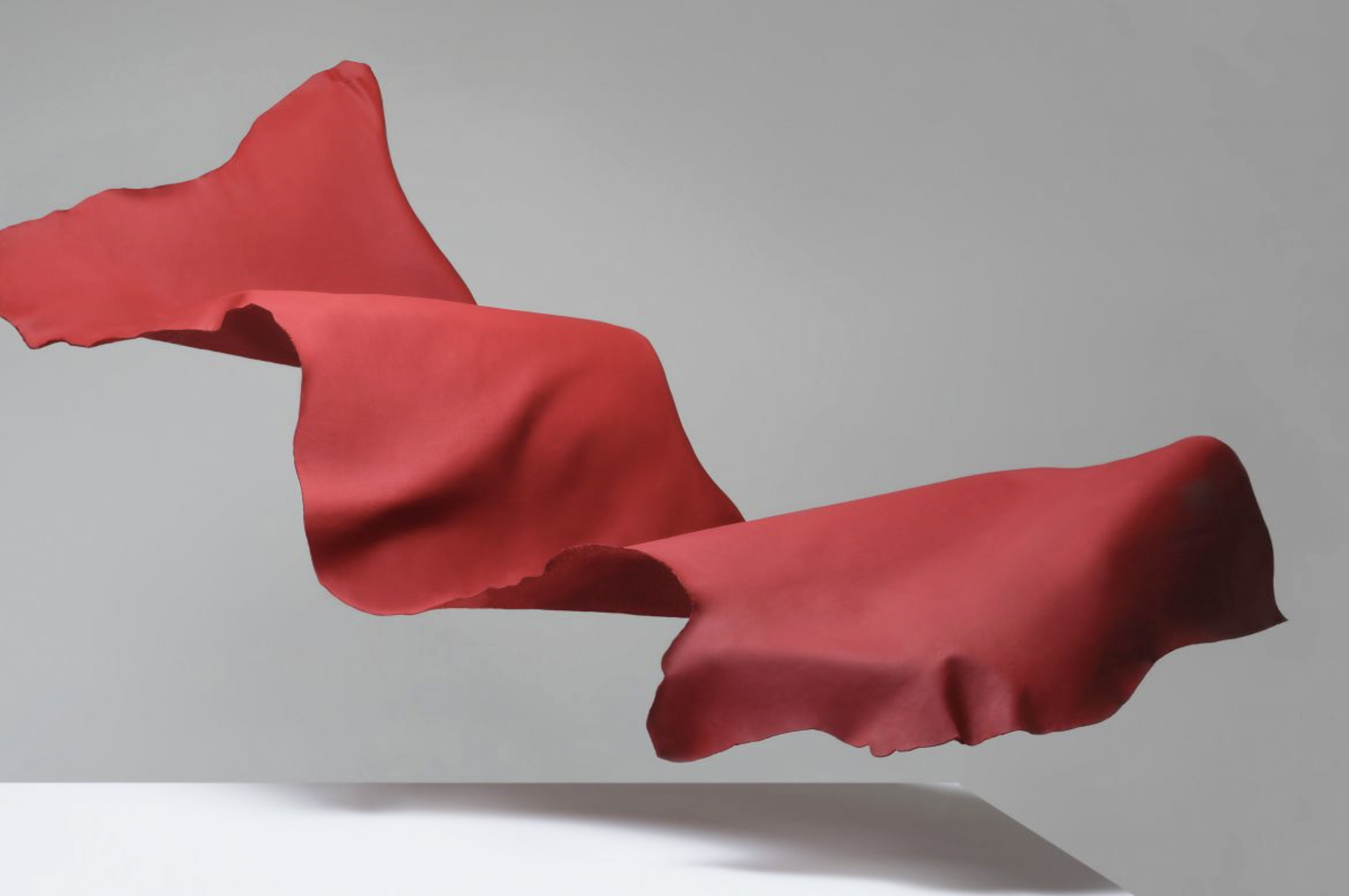

It will require some effort but you can find organic leather though it will be more expensive than non organic leather. To be classified organic, the hide must have come from an animal raised on an organic farm and have been dyed without using harmful chemicals - so vegetable dyes. It's estimated that only 10 per cent of leathers are vegetable dyed, the vast majority will have been dyed using chromium.

In complete contrast, all the hides she uses come from rare breed cows grown on small organic UK farms and tanned in Scandinavia. 'Rare breeds are typically kept in smaller herds by people who love them, and it shows in the end product,' she says. 'The happier and healthier the animal, the better the leather.

One thing to look out for and avoid is leather that can be wiped down with water. That's because wipe-clean leather is invariably a composite of cheap hide with a plastic coating on top. Hence it's far better to seek out vegetable tanned products such as handbags and shoes.

Rowan Gabrielle at Organic Leather takes the hides of cattle reared on Exmoor and has them tanned in Devon. 'Our primary focus is on how our leather is tanned, as that is where we can best prevent further toxicity entering our environment and our bodies,' she says. 'Our tanneries only use natural materials such as bark tannins, plant tannins, lime or smoke to cure, preserve and tan leather; these are all biodegradable.'

While tanning with chromium can be done in under a week, vegetable tanning takes from five weeks to 12 months, which is a huge difference in terms of cash flow and storage space. Nonetheless, some larger companies are also taking the plunge. At Bridge of Weir around a third of the leather is now tanned using tannins from the bark of the black wattle tree, sustainably farmed in African countries.

Bridge of Weir, along with sister company Andrew Muirhead, are part of Scottish Leather Group, which is at the forefront of a move towards cleaner, more environmentally-friendly tanneries on a large scale. But SLG’s environment director Dr Warren Bowden explains it isn’t necessary to use vegetable tannin to clean up the industry: 'Vegetable tanning extracts principally provide an alternative ‘feel and property’ to the leather. But it's not necessarily driven by health and safety or environmental criteria.”

That's because when chromium is used in the group's tanning process, it's recaptured from the waste water to avoid contamination then re-used. 'We promote the concept of sustainable leather manufacture by considering our waste as a resource,' says Dr Bowden. He explains that Scottish Leather Group runs its own thermal plant run on waste and this makes the companies self-sufficient in energy.

The tanneries have now achieved zero waste. 'This is unique and sets us apart from the global leather industry. And despite being one of the lowest water users globally because our processes are so efficient, we have also built an ultrafiltration plant which produces clean effluent, as the first stage in our bid to ‘close the loop’ and recycle water back into production. Our energy use per hide is as little as 1/5th of our competitors published data and our water use is less than half.'

What about vegan leathers?

Vegans obviously do not want animal leather in their lives and faux leathers mean they get the leather look and the leather strength without any animals having died. Mmm, but the problem with what could be called first generation faux leather is that it's made from plastic - ie it's derived from fossil fuels and is the antithesis of eco friendly. However, plant or vegan 'leathers' have come on leaps and bounds in recent years and they're certainly a great alternative to real leather for items such as trainers and bags. (Note, vegan leathers are not always totally plastic free so you must do due diligence and ensure what you're buying is what you think you're buying). Good plant leathers are derived from pineapples (Piñatex), mushrooms (mylo) cacti (Desserto) and grapes (Vegea). A good place to buy is Alternative Leathers which sells here and in the US.

The trade body Leather UK says it wants to help younger generations understand leather and misconceptions around it and around so called vegan leather. It has launched a guide which can be read here.